Add to Cart

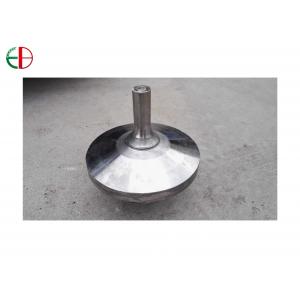

Precision casting refers to the general term for the precision casting process.

Compared with the traditional sand casting process, the precision casting size is more precise and the surface finish is better.

It includes: investment casting, ceramic casting, metal casting, pressure casting, die casting.

Precision casting and lost wax casting, its products are precision, complex, close to the final shape, can not machining or rarely used directly, so the investment casting is an advanced technology of formed near net shape.

Quality Level: As per National Standard & International Standards.

Special Features:

1. We can make Valve casting parts with Lost Wax Cast Process

2. We polished the surface of the casting.

Production Process: Investment Process,including machining process.

Material Grade:

| KS | ASTM AISI | Chemical Composition | Mechanical Properties | ||||||||||||

| C | Si | Mn | P | S | Ni | Cr | Mo | W | CO | Yield strength (N/㎟) | Tensile strength (N/㎟) | Elongation (%) | |||

| HA | ≦2.00 | ≦1.00 | 0.35~0.65 | ≦0.040 | ≦0.040 | - | 8.00~10.00 | 0.90~1.20 | - | - | |||||

| HRSC1 | - | 0.20~0.40 | 1.50~3.00 | ≦1.00 | ≦0.040 | ≦0.040 | MAX 1.00 | 12.00~15.00 | ≦ 0.50 | - | - | - | ≧490 | ≧10 | |

| HRSC2 | HC | MAX 0.40 | ≦2.00 | ≦1.00 | ≦0.040 | ≦0.040 | MAX 1.00 | 25.00~28.00 | ≦0.50 | - | - | - | ≧340 | - | |

| - | MAX 0.40 | ≦2.00 | ≦1.00 | ≦0.040 | ≦0.040 | MAX 1.00 | 12.00~15.00 | ≦0.50 | - | - | - | ≧490 | - | ||

| HRSC11 | HD | MAX 0.40 | ≦2.00 | ≦1.00 | ≦0.040 | ≦0.040 | 4.00~6.00 | 24.00~28.00 | ≦0.50 | - | - | - | ≧590 | - | |

| 0.30~0.40 | ≦2.00 | ≦1.00 | ≦0.040 | ≦0.040 | 3.50~4.50 | 26.00~30.00 | 0.30~0.50 | - | - | ||||||

| HRSC12 | HF | 0.20~0.40 | ≦2.00 | ≦2.00 | ≦0.040 | ≦0.040 | 8.00~12.00 | 18.00~23.00 | ≦0.50 | - | - | ≧235 | ≧490 | ≧23 | |

| HRSC13 | HH | 0.20~0.50 | ≦2.00 | ≦2.00 | ≦0.040 | ≦0.040 | 11.00~14.00 | 24.00~28.00 | ≦0.50 | - | - | ≧235 | ≧490 | ≧8 | |

| HH2 | 0.25~0.50 | ≦1.75 | ≦2.50 | ≦0.040 | ≦0.040 | 12.00~14.00 | 23.00~26.00 | ≦0.50 | - | - | ≧235 | ≧490 | ≧8 | ||

| HRSC15 | HT | 0.35~0.70 | ≦2.50 | ≦2.00 | ≦0.040 | ≦0.040 | 33.00~37.00 | 15.00~19.00 | ≦0.50 | - | - | - | ≧440 | ≧4 | |

| HRSC16 | HT30 | 0.20~0.35 | ≦2.50 | ≦2.00 | ≦0.040 | ≦0.040 | 33.00~37.00 | 13.00~17.00 | ≦0.50 | - | - | ≧195 | ≧440 | ≧13 | |

| HE | 0.20~0.50 | ≦2.00 | ≦2.00 | ≦0.040 | ≦0.040 | 8.00~11.00 | 26.00~30.00 | ≦0.50 | - | - | ≧275 | ≧540 | ≧5 | ||

| HI | 0.20~0.50 | ≦2.00 | ≦2.00 | ≦0.040 | ≦0.040 | 14.00~18.00 | 26.00~30.00 | ≦0.50 | - | - | ≧235 | ≧490 | ≧8 | ||

| HN | 0.20~0.50 | ≦2.00 | ≦2.00 | ≦0.040 | ≦0.040 | 23.00~27.00 | 19.00~23.00 | ≦0.50 | - | - | - | ≧390 | ≧5 | ||

| HU | 0.35~0.75 | ≦2.50 | ≦2.00 | ≦0.040 | ≦0.040 | 37.00~41.00 | 17.00~21.00 | ≦0.50 | - | - | - | ≧390 | ≧4 | ||

| HK | 0.20~0.60 | ≦2.00 | ≦2.00 | ≦0.040 | ≦0.040 | 18.00~22.00 | 24.00~28.00 | ≦0.50 | - | - | ≧ | ≧340 | ≧ | ||

| HRSC21 | HK30 | 0.25~0.35 | ≦1.75 | ≦1.50 | ≦0.040 | ≦0.040 | 19.00~22.00 | 23.00~27.00 | ≦0.50 | - | - | ≧235 | ≧440 | ≧8 | |

| HRSC22 | HK40 | 0.35~0.45 | ≦1.75 | ≦1.50 | ≦0.040 | ≦0.040 | 19.00~22.00 | 23.70~27.00 | ≦0.50 | - | - | ≧235 | ≧440 | ≧8 | |

| HK40 | 0.35~0.45 | ≦1.75 | ≦1.50 | ≦0.030 | ≦0.040 | 20.00~23.00 | 23.00~26.00 | ≦0.50 | - | - | High press | ||||

| HL | 0.20~0.60 | ≦2.00 | ≦2.00 | ≦0.040 | ≦0.040 | 18.00~22.00 | 28.00~32.00 | ≦0.50 | - | - | ≧245 | ≧450 | ≧8 | ||

| HL-30 | 0.25~0.35 | ≦2.00 | ≦1.50 | ≦0.040 | ≦0.040 | 18.00~22.00 | 28.00~32.00 | ≦0.50 | - | - | |||||

| HL-40 | 0.35~0.45 | ≦2.00 | ≦1.50 | ≦0.040 | ≦0.040 | 18.00~22.00 | 28.00~32.00 | ≦0.50 | - | - | |||||

| 0.25~0.35 | 1.00-1.50 | 1.00-1.50 | 19.00~21.00 | 29.00~31.00 | - | 1.25-1.75 | - | ||||||||

| 0.25~0.35 | ≦2.00 | ≦1.00 | 19.00~21.00 | 29.00~31.00 | - | 1.00-2.00 | - | ||||||||

| 0.34-0.45 | 29.00-31.00 | 33.00-35.00 | 4.00-6.00 | Ti0.15-0.35 | |||||||||||

| 0.25-0.35 | 28.00-32.00 | 24.00-26.00 | 1.50-2.50 | Nb1.00-2.00 | |||||||||||

| HP | 0.35~0.75 | ≦2.00 | ≦2.00 | ≦0.040 | ≦0.040 | 33.00~37.00 | 24.00~28.00 | ≦0.50 | - | - | ≧235 | ≧440 | ≧5 | ||

| 0.40~0.50 | ≦1.50 | ≦1.50 | 34.00~36.00 | 26.00~28.00 | - | 1.00-2.00 | - | ||||||||

| 0.37~0.47 | ≦1.50 | ≦1.50 | 34.00~37.00 | 24.00~28.00 | 1.00~1.50 | - | - | ≧245 | ≧440 | ≧8 | |||||

| HW | 0.35~0.75 | ≦2.50 | ≦2.00 | ≦0.040 | ≦0.040 | 58.00~62.00 | 10.00~14.00 | ≦0.50 | - | - | ≧ | ≧390 | ≧4 | ||

| HX | 0.35~0.75 | ≦2.50 | ≦2.00 | ≦0.040 | ≦0.040 | 64.00~68.00 | 15.00~19.00 | ≦0.05 | - | - | ≧ | ≧390 | ≧4 | ||

| MO-RE1 | 0.40~0.50 | 35.00~38.00 | 25.00~28.00 | MAX0.5 | 1.25-2.00 | - | ≧196 | ≧412 | ≧6 | ||||||

| MO-RE2 | 0.15~0.25 | 48.00~52.00 | 32.00~34.00 | MAX0.5 | 15.0-17.0 | - | ≧235 | ≧490 | ≧3 | ||||||

| Super22H | 0.40-0.60 | 46.00-50.00 | 26.00-30.00 | MAX0.5 | 4.00-6.00 | 2.50-4.00 | ≧196 | ≧441 | ≧6 | ||||||

| 0.30-0.50 | ≦2.00 | ≦2.00 | 31.00-35.00 | 26.00-30.00 | MAX0.5 | 1.00-2.00 | - | ≧196 | ≧412 | ≧6 | |||||

| NA22H | 0.40-0.60 | ≦2.00 | ≦2.00 | 45.00-50.00 | 25.00-29.00 | MAX0.5 | 4.00-6.00 | - | ≧196 | ≧412 | ≧6 | ||||

| 0.40-0.60 | max1.50 | max1.50 | 45.00-50.00 | 25.00-30.00 | - | 4.00-6.00 | - | ≧295 | ≧390 | ≧5 | |||||

| HOM | 0.30-0.50 | ≦2.00 | ≦2.00 | 33.00-37.00 | 24.00-28.00 | 1.00-2.00 | - | - | ≧196 | ≧412 | ≧6 | ||||

| 0.35-0.45 | max2.0 | max2.0 | 22.00-25.00 | 24.00-27.00 | 1.80-2.30 | - | 14.0-18.0 | ≧245 | ≧490 | ≧8 | |||||

| 0.40-0.50 | max0.5 | 0.30-0.60 | 47.00-51.00 | 28.00-31.00 | - | 12.0-14.0 | - | ≧295 | ≧490 | - | |||||

| MAX0.15 | 15.00-19.00 | 25.00-29.00 | 0.50-1.50 | - | 38.0-42.0 | ||||||||||

| 0.05-0.12 | - | 26.00-30.00 | - | - | 47.0-52.0 | ||||||||||

| UMCO-50 | 0.05-0.12 | 0.5-1.0 | 0.5-1.0 | MAX0.02 | MAX0.02 | - | 27.00-29.00 | - | - | 48.0-52.0 | |||||

| URM | 0.10-0.20 | 40.0-42.0 | 32.0-34.0 | - | 0.3-0.6 | - | |||||||||

Step 1: Getting orders.

Production Flow Chart

Step 2: Process design by technical department

Step 3: Purchase of raw materials and pattern making &checking

Step 4: Inspection of raw materials

Step 5: Melting by middle-frequency induction furnaces

Step 6: Ladle analysis by Spectrometer

Step 7: De-oxidization, slag-removal, tapping

Step 8: Pouring

Step 9: Openning & fettling

Step 10: Surface & dimensional check

Step 11: Heat treatment

Step 12: Inspection of physical property (UT test,MT test, hardness,impact value, matrix structure)

Step 13: Packing

Step 14: Shipping

![]()

1. 18-year Foundry Operation Experience.

2. Friendly & High Efficient Technical & Commercial Communication.

3. Professional Export Practices: Have Exported to +60 Overseas Countries.

Our Trade Show

Our booth No. 14-A29-5 in Newcast 2015,Germany

Hall 14, Stand No.A29-5.

Contact Us for further information about products & service:

Mr.John Liu

Project Manager

Tel: 0086-188 0059 6372

Fax: 0086-510-6879 2172

E-mail: cast@ebcastings.com,ebcasting@126.com

Skype ID:julia.zhu26

QQ: 217 039 6403

www.ebcastings.com

Eternal Bliss Alloy Casting & Forging Co.,LTD.

Add.: J-Sci-Tech Park, Binhu District,Wuxi,214122, Jiangsu,China